The Tenecor® Story

Our History.

Tenecor® was established in the mid 1970's when acrylic aquariums did not exist. There was no internet or "how-to" online videos. We were the first company to build hobbyist acrylic aquariums and many of the processes Tenecor® developed have become industry standards.

Anyone can build an acrylic aquarium. Few companies can build a great aquarium.

The biggest mistake shoppers make when evaluating acrylic aquarium manufacturers is assuming all companies have the same level of quality. This is absolutely not the case. For example, some companies who started out making glass tanks find themselves overwhelmed with the complexities of trying to fabricate an acrylic aquarium. They end up trying to learn along the way and the end results are not pretty. We know this because often their customers call us and frantically ask if we can help fix their tanks.

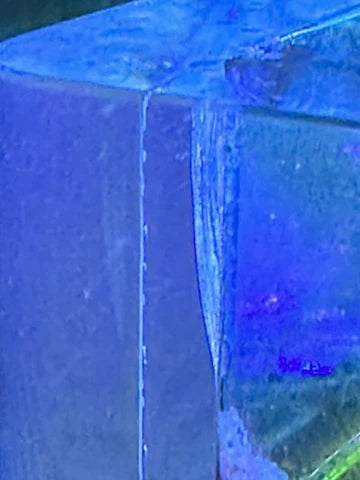

One memorable example is a hobbyist who bought an acrylic aquarium with an external overflow from another company. One week after he got his tank up and running, the entire overflow broke off! Another hobbyist sent us the images below of two rimless frag tanks he purchased from a well known California fabricator. The top image shows the walls beginning to come apart. Not only is this an example of poor bonding, the overall design of this tank is incorrect. It is just a matter of time before the entire seam splits.

An example of poor bonding and poor design. Customer provided image. His entire story was posted on a saltwater reefing forum.

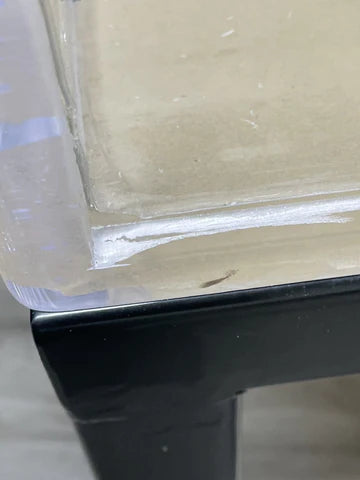

Another example of poor edge prep and poor bonding. Also, notice the rounded radius edges. Tenecor does not round edges because this weakens the seams.

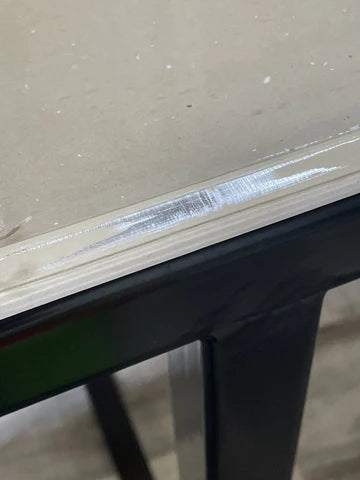

Yet another example of poor edge prep and improper bonding technique.

Edge preparation, bonding techniques, tooling and material handling requirements for manufacturing acrylic aquariums are vastly more complicated than putting together a simple glass tank. And many acrylic "companies" are often no more than garage operations with a table saw and a router.

Seam quality is not always what it seems.

Seam quality matters and getting good seams is not easy, especially on larger tanks. Bubbles, poor welds and imperfectly aligned panels are common mistakes made by garage fabricators with limited acrylic experience. For good seams the edges must be flat, smooth and level. Then the two bonding surfaces must be perfectly aligned with each other as well as being square and true. This is not easy on a small aquarium and very difficult on larger tanks.

All glass tanks will eventually leak. Every single one.

Glass tank seams are joined with silicone that over time become less pliable and weaken. Whether it is two years or ten, all glass tanks will eventually develop leaks. Properly constructed acrylic seams are chemical bonds at the molecular level, impossible to take apart and virtually leakproof. With a Tenecor® aquarium, you can sleep well at night without the worry of flooding your home.

Experience. We have built more acrylic aquariums than anyone.

Tenecor® has been building acrylic aquariums since the late 1970's. Simply put, we have built more of them than anyone. And we build hundreds of them. On any given day, we build more acrylic aquariums and accessories than many shops do in an entire year. The "combined experience" touted by some smaller outfits cannot replace our historical skill set.

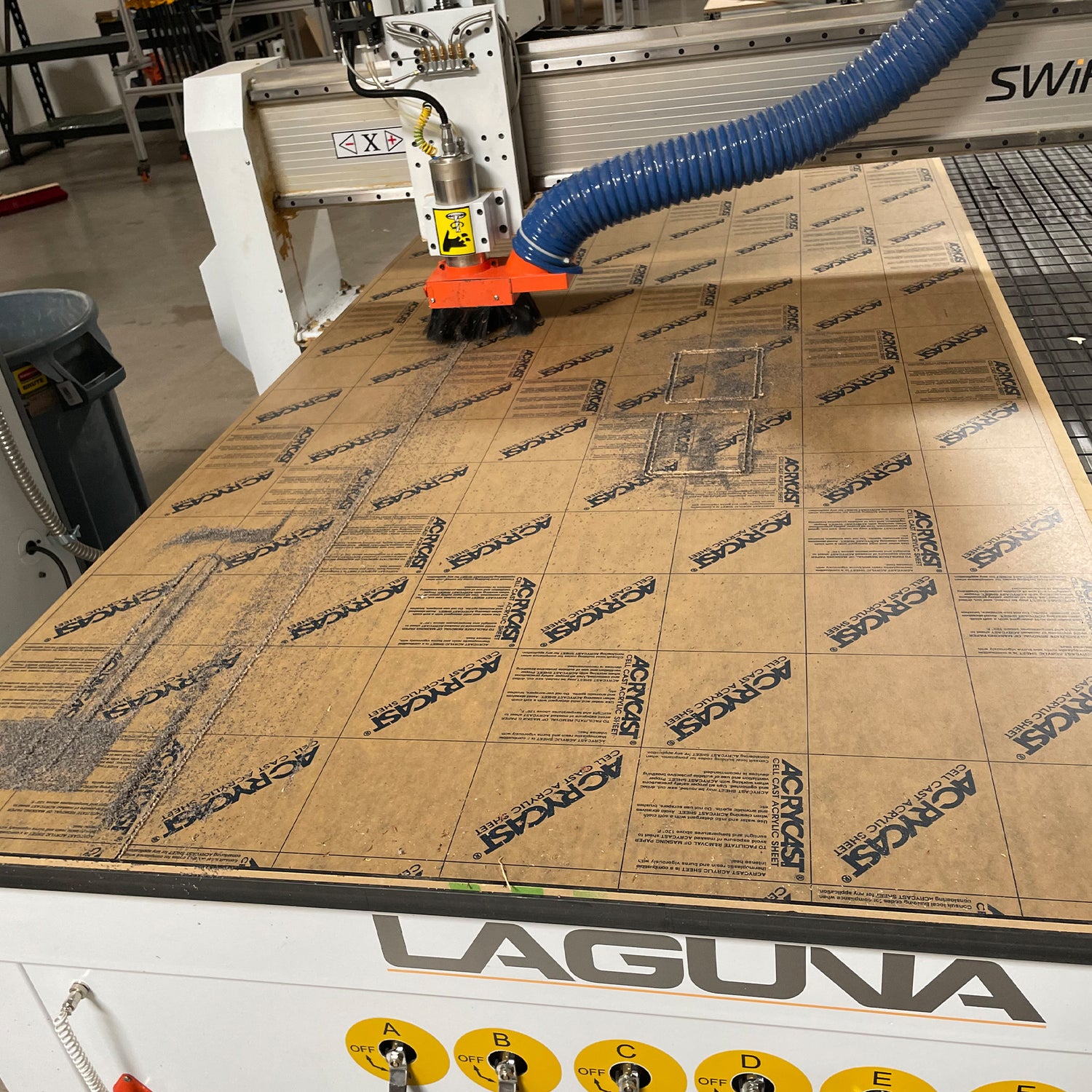

Production capabilities. CNC automation is essential.

The production equipment matters. Our facilities are highly automated and include several (really big and expensive) CNC routers, lasers and digital design capabilities. We can build a single dream tank for you or an entire store or several stores like the ones we designed and built for PetSmart®. As one of the first acrylic aquarium fabricators, many of our innovations have become industry standards. And Tenecor® is where many smaller fabricators, especially in the metro Phoenix market first learned how to put together their first fish tank.

The All In One Aquarium. Tenecor® designed and built the first one.

Another Tenecor® innovation over 40 years ago, was installing the filter into the back of the tank. Back then the phrase "AIO" did not exist. Putting the filter inside the tank was not easy since acrylic aquariums have tops as well as bottoms. It was like building a ship in a bottle. In glass tanks you can easily silicone in some pieces for an AIO. If you make a mistake, take it apart and start over. Not so with acrylic. Once the pieces are bonded, they cannot be taken apart. It still isn't easy which is why Tenecor remains the only company making a full range of wet/dry acrylic AIO aquariums.

Simplicity™ AIO. Safe. Reliable. A great value.

The appeal of the Tenecor® Simplicity™ aquarium was the same forty years ago as it is now: Easy to set up with no holes to drill and no worry about leakage. Best of all, they were a great value. In 2022, Simplicity™ was replaced by the registered trademark name Advantage® Aquariums.

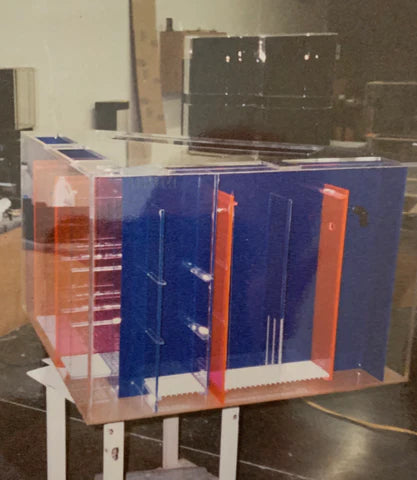

Tenecor® built the first acrylic All in One Aquarium. Here is one from 1978. It was a wet/dry design and a corner pentagon. Each piece was cut manually with no CNC equipment. This same tank today with CNC takes us a fraction of the time to build and with tighter tolerances.

The newest Advantage® AIO designs feature removable media cups and unbreakable polycarbonate lids and trickle plates. The top cups are used to hold filter floss for mechanical filtration. The bottom cups can also be used for mechanical filtration or for carbon. Advantage® AIO's are offered in more sizes and styles than ever before.

PetSmart®

In the early 90's, Phoenix based PetSmart® asked us to evaluate their store systems. Their existing aquariums were poorly constructed and their store systems were inefficient with extremely high fish losses. They were going public and needed several hundred installations. We designed their systems and built many of their stores.

One of the early PetSmart® stores we built. On the far left is the refrigerated goldfish feeder tank. Notice the segmented return lines. This was the first application in the aquarium hobby of Loc Line returns. Each tank can be isolated and be independent of the others.

PetSmart's® 700 gallon freshwater tank with center overflow. We built dozens of these. The walls are one inch. The center overflow has a dry raceway for electrical to the canopy. Filtration is a simple canister style pool filter. We also added closed loop reverse flow undergravel filtration and inline heater.

-

It's all about choice and made to order flexibility.

Flexibility is designed into our manufacturing capabilities. The added benefit of CNC technology which was rare and expensive forty years ago is critical for modern production. What took hours of manual calculations and cutting can now be done in a fraction of the time on one of our CNC routers or CO2 lasers. Our production lines can go from a twenty gallon to a 120 gallon, back to a 40 followed by a 65 without any downtime or retooling. This is how we can offer an almost unlimited selection of sizes, styles and varieties.

-

Big tanks are a Tenecor® specialty.

Glass tanks have numerous disadvantages, starting with safety and the incredibly heavy weight, over 1,000 pounds for larger sizes. The upper limit of glass tanks is around 300 gallons and around 20 inches in height. Where glass tanks max out, our large tank portfolio begins. We have the specialized tooling and equipment necessary for building the big boys.

-

Tenecor® today continues to be the leading builder of acrylic aquariums.

Tenecor® has built more acrylic aquariums than anyone. Our manufacturing capabilities span three buildings, staffed with highly trained American craftsmen. State of the art equipment and software continue to keep us well ahead of the competition in innovation and product quality.

An original 12 gallon tabletop corner pentagon with built Simplicity™ AIO filtration. This was the aqua dome model. Going strong for over 45 years.

Tenecor® aquariums last a long, long time.

Hundreds of thousands of Tenecor® aquariums are still in operation.

Another corner pentagon. Approximately 30 years old. It sits on one of our original Unitex Stands with matching canopy. Still looks as new as the day it was installed.

Our newest corner pentagon design with one piece back wall. Notice there is no seam at the 90 degree back corner.

One of our newest overflow designs with quad removable media cups. The cups can be used as pre filters, chemical or both. All are removable.

Eight foot peninsula with quad cup overflow. Cups are four inches in diameter. Larger sizes have seven inch cups.

Vista View corner tank. One piece viewing panel. This tank is approximately 25 years old..

-

AIO Peninsula frag tank. One of our smaller tanks.

-

450 Gallon Peninsula on a Magnum stand.

-

CNC machined top ready for assembly. Edges are flat, square and level to millimeters. Only Tenecor® has this size CNC capability.

We do not add junk components to keep our package costs low. Many outfits will include cheap low quality pumps, lights and other gear only to have the customer replace them at additional cost. This is especially true with the Nano and desktops from other outfits. Only premium brand name components are found in a Tenecor®.

American made since 1980.

Tenecor® still designs and manufactures in the great state of Arizona USA and does not offshore, outsource, subcontract or use third party manufacturers.